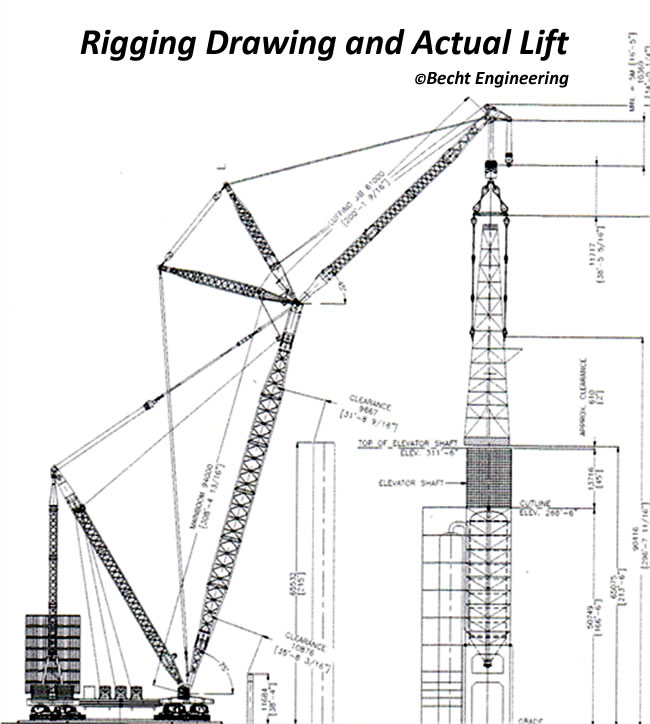

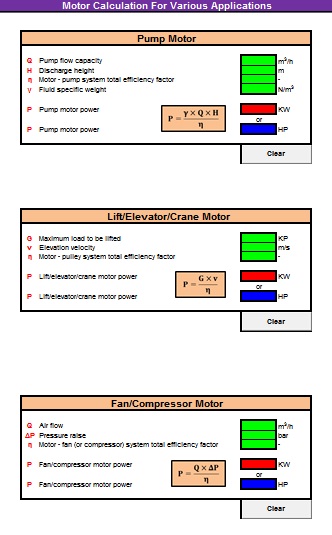

Certificates issued are valid for 3 years from the date of training.When it comes to heavy lifting on job sites, rarely is there a one-size-fits-all approach to renting a crane. It is a closed book exam and students must achieve a passing grade of 70% to pass. Students will have a brief review period and then a final exam will be issued. Students are also taught how to have thorough pre-lift meetings and how to assign responsibilities prior to the lift. Crews then execute their plan, with direction given to ensure proper rigging practices.They are then required to develop a rigging plan, crane set-up plan, and a lift calculation. Crews are broken into groups and given a rigging scenario.This portion requires coordination prior to training to ensure cranes and equipment are available. If necessary, a knuckle boom can be provided with small lifts to demonstrate hand rigging. This portion of the course is site dependent on equipment and cranes available. Learn how to understand operators manuals and charts for multiple cranes.Learn terminology and proper steps to complete lift calculations.Overview of safe practices when working around a crane such as bad side of the load, etc.Ĭhapter 6: Load Charts and Lift Calculations.Overview of cold weather effects on cranes and rigging.Overview of safe work practices around powerlines with legislation reviewed on safe.Learn proper hand signals for crane operation.Learn about all the different configurations of rigging and how to properly apply.Students are taught how to safely and practically determine sling angles and tension. Learn how to properly size rigging for a job.Properly understand how to use a rigging capacity chart.Learn about D/d Ratios and how to safely apply them to rigging.

Learn and review different codes and legislation including CSA, OH&S (multiple provinces referenced), ANSI, and ASME requirements.

0 kommentar(er)

0 kommentar(er)